Complete and accurate product data is required for efficient distribution, increasing sales, and enhanced inventory visibility and traceability processes. This vital information is available in the GS1 Global Data Synchronization Network™ (GDSN®)—the one source of complete product information for the industry. Now is the time to get engaged!

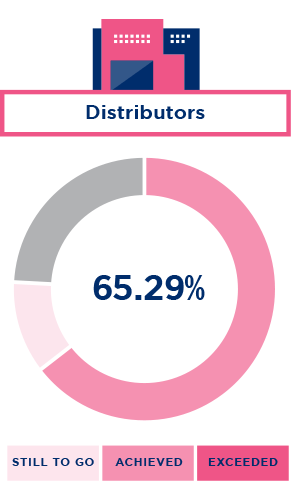

Goal = 75% GDSN Adoption by Sales Revenue Based on Usage*

We measure adoption by company participation in the GDSN and then work with the industry associations to tie revenue to participating companies.

Operational Data

Companies share simple data (product dimension, weight,

etc.) to streamline the flow of products through the supply

chain. Totals as of September 30, 2015.

Number of Products Being Shared

Sales Data

Companies begin sharing richer product data including

marketing descriptions, images, allergens, and nutritional

information to increase customer trust and sales. Totals as

of September 30, 2015.

Number of Products Being Shared

Operational and Sales Data

Totals as of Q3 2020.

Total Products in GDSN

“ Shamrock has seen a 20 percent increase in sales and a 14 percent increase in demand for those products that have extended data attributes such as nutritional information and images.” Bryan West

Senior Director of Information Systems

Challenge

Shamrock Foods (Shamrock) needed complete and accurate

data for its web-based ordering system to satisfy the

increasing demands of its customers, especially healthcare

providers and school systems that require nutritional and

allergen information before purchasing. The company also

understood how using quality data could help it become

more efficient and cut costs throughout its operations.

Solution

The Shamrock team created a new supplier connection

process for its vendors to publish their product data and

images in its electronic ordering system for customers.

The team used multiple venues to reach its suppliers,

requesting their participation and offering guidance via

the Foodservice GS1 US Standards Initiative. Today, more

than 500 Shamrock suppliers publish detailed product

information as well as share and synchronize data via the

GDSN.

Benefits

Shamrock advises it has experienced a 20 percent increase

in sales and a 14 percent increase in demand for those

products that have extended data attributes such as

nutritional information and product images. The company

has increased its level of customer service by providing

extended product information to help them make better

buying decisions.

“ While quality data can reduce costs, we have found it significantly increases sales.” Cullen Andrews

Director of National Accounts

Challenge

Dot Foods (Dot) introduced its online product

catalogue—the Dot Expressway®

(Expressway)—18 years ago to provide better search

capabilities for its customers and sales representatives.

With about 105,000 products from 700 suppliers, Dot wanted

to fully leverage its market advantage by expanding and

enhancing the Expressway with more complete and accurate

product information.

Solution

Dot launched a data quality initiative that transformed

the Expressway to include expanded and validated data

attributes. Dot suppliers publish core item attributes

such as case dimensions and weights as well as marketing

and nutritional information like ingredients, allergens,

and images through data pools that are then synchronized

with Dot's system via the GDSN.

Benefits

Today, the Dot Expressway receives about 1.5 million hits

per month from its users, including nearly 2,800

distributors and 310 national account operators.

Distributors and Dot's sales representatives use the

Expressway when selling to customers for increased sales.

With accurate data, Dot has reduced costs with improved

warehouse management, load optimization, and increased

productivity.

“ With accurate, up-to-date data we can optimize truck loads, maximize freight costs, and be more competitive in the marketplace. That's the power of automated quality data.” Steve Reiling

Director of Non-Foods Purchasing and Supply Chain Initiatives

Challenge

Texas food distributor, Ben E. Keith Company serves 18,000

foodservice operators in 11 states throughout the

Southwest. When automating operations, the company knew

that complete and accurate data was a critical component

to effectively transform processes, making every part of

its business more efficient and responsive to customers.

Solution

Ben E. Keith launched a quality data program that enables

manufacturers to publish—via data pools—core

data attributes, marketing and nutritional information,

and images that are then synchronized with the company's

system via the GDSN. Entrée, the company's e-commerce

application, delivers this complete, up-to-date product

information to customer desktops or mobile

devices—allowing them to research products, place

orders, check on deliveries, and much more.

Benefits

Ben E. Keith manufacturers that supply some 80 percent of

all products are participating in the company's quality

data program. With easy access to better product data, Ben

E. Keith sales reps can more easily sell and serve

customers for increased sales. All aspects of the

company's operations, from purchasing to logistics, are

using quality data to increase efficiencies and improve

customer service.

“ We estimate just over a million dollars in transportation and material handling costs alone will be avoided going forward—just by achieving accurate data for these 83 products.” Lucelena Angarita

Director, Supply Chain Traceability

Challenge

Independent Purchasing Cooperative (IPC) is a SUBWAY®

franchisee-owned and operated purchasing cooperative. With

an eye on freshness and quality, IPC wanted to achieve

traceability of suppliers' products as they travel to

SUBWAY® restaurants. To do this, IPC

realized it needed accurate product data, yet found

widespread inaccuracies that were adding costs and

inefficiencies throughout its supply chain.

Solution

IPC launched a data quality initiative, using the GDSN. As

suppliers publish core item data in the GDSN, IPC reviews

the data for inconsistencies. Using GS1 best practices for

packaging measurements, distributors conduct physical

product audits to identify further data discrepancies.

Suppliers then update their product data in the GDSN,

creating a single source of truth for all partners.

Benefits

Suppliers have published 90 percent of product data by

volume in the GDSN, making corrections as IPC and its

distributors identify discrepancies. In addition, 89

percent of distribution centers are receiving and working

on integrating this product data into their management

systems for improved transportation, logistics, and

warehouse management. IPC estimates significant costs

savings; for example, after achieving accurate data for 83

major products, IPC estimates approximately a million

dollars in cost avoidance in material handling and

transport costs alone.

“ We are seeing an increasing number of withdrawals and recalls due to allergens and incomplete labeling. It's becoming more and more important that we work together to share complete data, and if needed, to quickly and accurately find product.” Syndee Stiles

Vice President, Operations Support

Challenge

With more than 3,600 restaurants in 18 countries,

DineEquity is one of the largest full-service restaurant

companies with two iconic American flagship

brands—Applebee's® and

IHOP®. The company wanted to take steps to

achieve traceability for increased food safety for its

franchisees' restaurants and their hundreds of thousands

of customers who dine at these restaurants each day.

Solution

DineEquity is collaborating closely with McLane

Foodservice (McLane), an industry supply chain leader and

one of its major distributors, to implement case-level

traceability across its entire system. Drawing on McLane's

experience with GS1 Standards, DineEquity approached its

suppliers about the value of using GS1 Standards. Today,

many of DineEquity's suppliers use GS1-128 barcodes that

carry detailed product information to its distributors'

centers.

Benefits

Taking a standards approach, all players in the

foodservice supply chain can streamline their processes

and gain efficiencies by using quality data. DineEquity

and McLane know precisely what products have been

delivered to the exact restaurant locations for faster,

more precise recalls and withdrawals, if required. This

leads to improved food safety, brand protection, and

continued consumer confidence.

“ Getting complete and accurate data is an industry movement now—not just one company requesting, but multiple voices asking for what they need to be successful.” Dave Devlin

Vice President of Vendor Engagement

Challenge

Representing more than 450 distributor members and 960

locations, UniPro Foodservice (UniPro) continuously looks

for ways to help its members gain efficiencies while

meeting evolving customer demands. Increasingly,

foodservice operators expect and need valuable allergen

and nutritional data. With more than 138,000 products from

manufacturers, UniPro members needed an effective way to

search for and access complete and accurate product data.

Solution

UniPro worked closely with member advisors to create the

UniPro Master Data Management (MDM) Portal. Using data

pools, manufacturers can now electronically publish core

attributes and marketing and nutritional attributes. All

data is then synchronized and shared with the MDM Portal

via the GDSN, giving members an efficient way to access

quality product information and images.

Benefits

Manufacturers can now quickly distribute comprehensive

information about their products to UniPro's hundreds of

member locations. Sales representatives and members also

save time when researching products and can make more

informed selling and purchasing decisions. UniPro believes

its members and their customers are happier with easy

access to allergen and nutritional information.

“ With accurate and complete product data at our fingertips—direct from suppliers—we knew the benefits would be significant for our customers, our sales reps, our purchasing department, and even our suppliers.” Kevin Ahnert

COO, Pocono ProFoods

Challenge

Pocono ProFoods’ eight-person purchasing department spent significant time each day handling inquiries from sales representatives, customers, and in‑field buyers, requesting information about its vast portfolio of products. As demands for information grew, the mid-sized distributor decided to create a data management system comprised of complete, supplier-provided product data for efficient access by all.

Solution

The company launched an initiative that required suppliers to publish their product information via data pools and the Global Data Synchronization Network™ (GDSN®). Taking a step-by-step approach, the team implemented a campaign to collaborate with suppliers in publishing accurate and comprehensive product data, and then provided sales reps and their customers with online access to this information.

Benefits

To learn more, contact us at foodservice@gs1us.org